Diesel Exhaust Fluid (DEF) Open System containers are totes and drums that do not contain any valves to insert in the bung opening of the container. Either Colder or Micro Matic supplies such valves as per the DEF supplier. An “open system” allows for using a Pro Flow drum pump.

This “open system” container is an inexpensive option just like DEF pumps. Pro Flow Dynamics also provides a number of DEF pumps at economical prices. You can opt for anyone of them as per your needs.

How to Maintain Purity with an “Open System” Container?

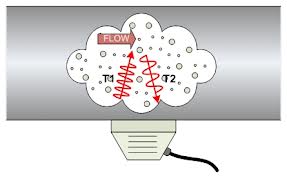

Pro Flow Dynamics has designed a wide range of bung adapters that seal the drum pump tube in the open system container. This adapter includes many micron filters to avoid contaminants from entering into the container.

The non-contaminating, high quality and inert materials that build the pump tube can help you maintain the purity. Hence, this is a secure product to keep various things safety.

Diesel Exhaust Fluid Pump Kits

Pro Flow Dynamics stores everything that is required to pump DEF into the storage tank of your vehicle. You can also select an individual item to build your own package as per your requirements.

- Stainless steel nozzle with an automatic shut off system for convenience

- Two series are available to maintain the flow

- Special DEF rated dispensing hoses

- Pump tube is matched to the size of container

- Unique bung adapter that avoids the contamination

High-quality DEF pumps and other products can be found on the website of Pro Flow Dynamics.

ProFlow Dynamic DEF Dispensing Equipment Supplier