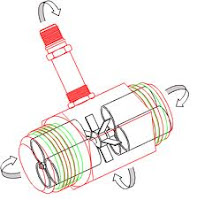

A turbine meter uses the mechanical energy of fluid for rotating a rotor i.e. “pinwheel” in the flow stream. Then the rotor shaft rotates rapid lyon bearings. When the fluid spins faster, the rotor automatically moves faster to a proportionate degree.

The shaft rotation can be sensed by examining the movement of blades or mechanically by itself. The movement of blade is normally noticed magnetically with blades or the embedded piece of metal producing a pulse. The turbine flow meter sensor is usually situated externally to the flowing stream to prevent any material of construction constraint.

The time fluid moves faster at its best, more pulses are produced. The transmitter processes the pulse signal to find out the flow of fluid. There are sensing and transmitters systems to sense the flow to both the forward and reverse directions.

How to Use the Turbine Flow Meter?

Turbine flow meter determines the velocity of gases, air, vapors, and liquids in pipes, like cryogenic liquids, hydrocarbons, industrial gases, water and chemicals. With the help of high accuracy turbine flow meters, it is easier to consider custody transfer of natural gas and hydrocarbons.

Such types of flow meters incorporate the functionality of the flow computer to correct for fluid properties, temperature and pressure to find out the preferred accuracy for specific applications.

Remember that using the turbine flow meter on fluid which are non-lubricating, as it can become inaccurate and even fail to run properly. So, keep all safety measures in mind and work on the turbine flow meter accordingly.

ProFlow Dynamics Supplies of Flow Meters

No comments:

Post a Comment